Development of Recycled Aluminum Alloy for the Manufacture of an Electrical Current-Conducting Tape

DOI:

https://doi.org/10.37256/aecm.5120243938Keywords:

recycled aluminum, gravity casting, homogenization, annealing, cold rolling, conductive tapeAbstract

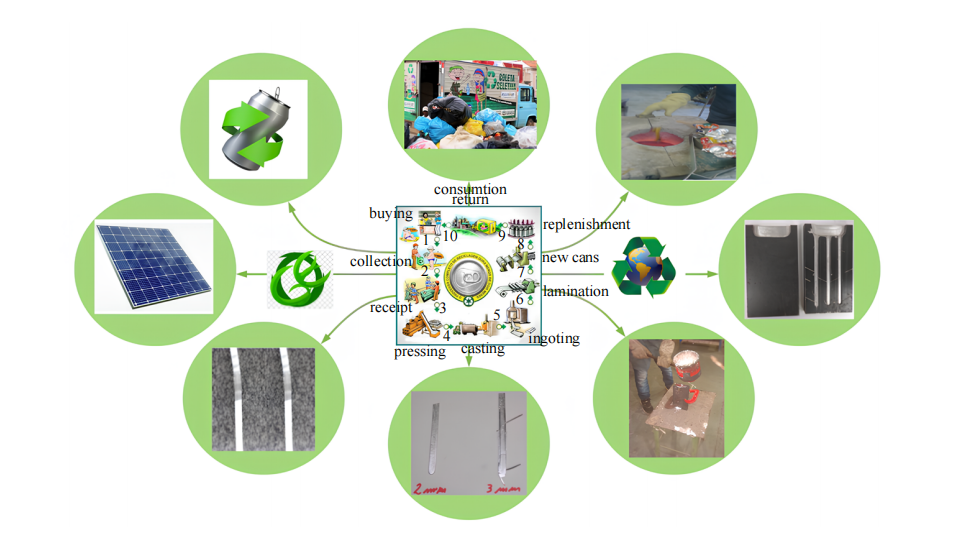

This research aimed to develop an electrical current-conducting tape using secondary aluminum (Al) obtained from recycled beverage cans. The gravity casting process was used, and Cu and Mg were added to assess the properties of the alloys. The evaluated alloys were from three groups of samples: (A) secondary Al; (B) Al-Cu; (C) Al-Cu-Mg. A homogenization process was applied to reduce the segregation of the heterogeneous structure of the cast ingots and to reduce the thickness of the tape to 0.5 mm, the cold rolling process was carried out. The samples were characterized by Vickers microhardness, tensile tests, hardening, anisotropy and electrical conductivity. After four lamination passes a reduction of 85.4% of the initial thickness was observed, reaching (0.59 ± 0.04) mm of final thickness. Subsequently to each lamination pass, the annealing process was applied to restore the material’s properties. The electrical conductivity presented results between 45.96 and 47.67 International Annealed Copper Standard (IACS), with a reduction of only 1.82% after lamination. Therefore, a tape with electrical conductivity and 0.59 mm thickness was obtained from recycled beverage cans aluminum. In addition, the characterization presented for the 3 samples will allow for the study of applications for these alloys and respective electrical conductive tapes.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Gilson Gilmar Holzschuh, Jorge André Ribas Moraes, Sérgio Boscato Garcia, Izete Zanesco, Adriano Moehlecke, Rosana de Cassia de Souza Schneider, Liane Mahlmann Kipper

This work is licensed under a Creative Commons Attribution 4.0 International License.